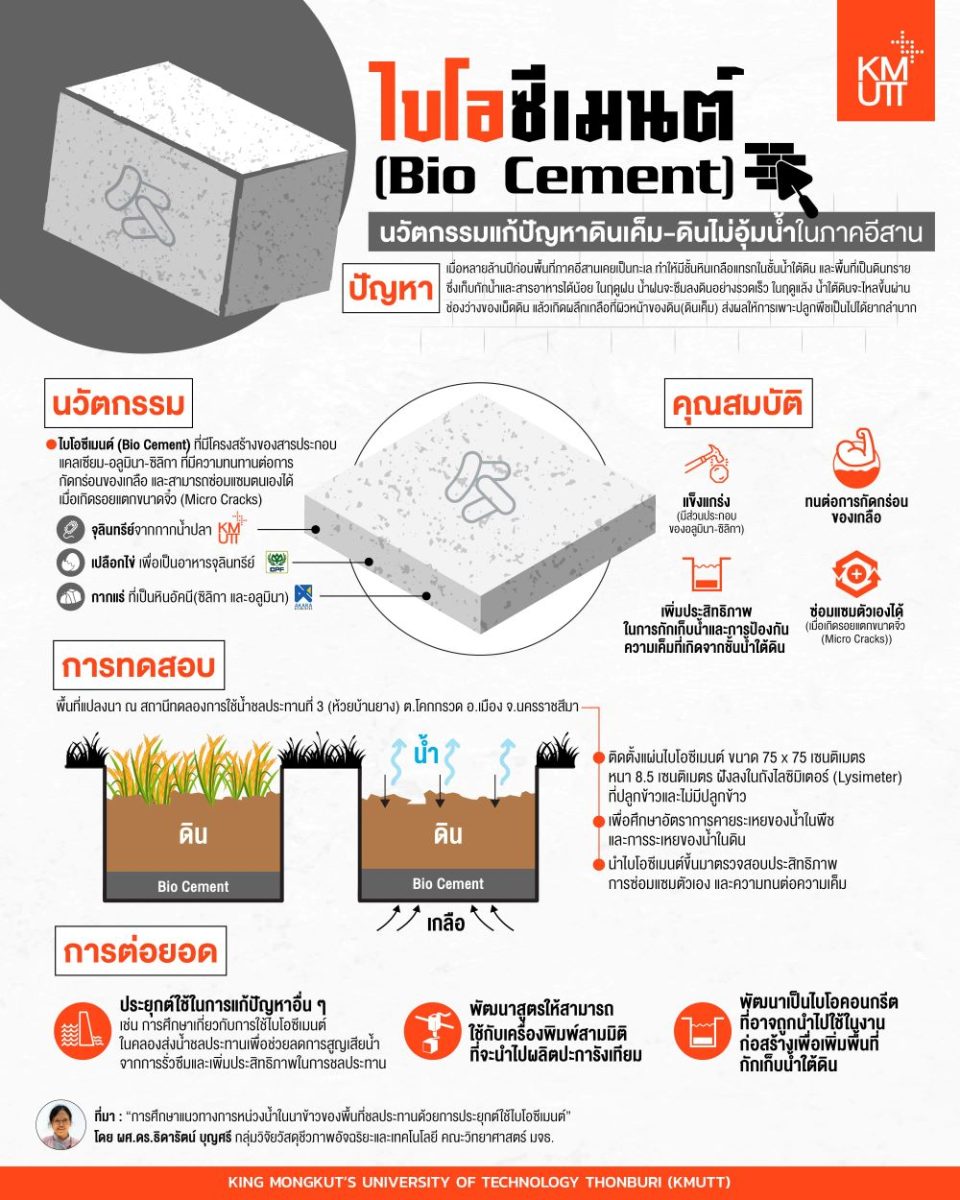

The problem of saline soil and soil that does not retain water is a major obstacle to farmers’ cultivation in the northeastern region of Thailand. This is because millions of years ago, this area used to be a sea, resulting in a layer of salt rocks interspersed with the underground water layer. The area is also sandy soil, which can retain little water and nutrients. In the rainy season, rainwater seeps into the soil quickly. In the dry season, underground water flows up through the gaps between the soil particles, forming salt crystals on the soil surface, making it difficult to cultivate crops. Therefore, this is an important issue that the Research and Development Office, Royal Irrigation Department, in collaboration with King Mongkut’s University of Technology Thonburi (KMUTT) has organized the project “Studying the Method of Water Retention in Irrigated Rice Fields by Applying Bio-Cement” to expand the results to solve the problem of soil salinity in rice fields and water management in rice fields with saline soil problems. The pilot experiment was conducted in the rice fields at the Irrigation Water Experiment Station 3 (Huai Ban Yang), Khok Kruat Subdistrict, Mueang District, Nakhon Ratchasima Province.

Asst.Prof.Dr. THIDARAT BUNSRI, a researcher from the Biosmart Material and Technology Research Group, Faculty of Science, KMUTT, said that Bio-cement is a cement made from a group of microorganisms that create limestone. Microorganisms are selected from fish sauce waste to create cement that can withstand salinity and repair itself. Combined with the creation of geopolymers, the result is cement that is strong and can hold water. Bio-cement materials can hold rainwater in the rainy season and reduce salt intrusion in the dry season, which may be used to increase the efficiency of water storage and prevent salinity from underground water.

“The production of bio-cement sheets is supported by local private companies. It consists of “egg shells”, which are waste materials from the hatcheries of CP Foods (Thailand) Public Company Limited in Chaiyaphum and Nakhon Ratchasima provinces, mixed with “mineral waste”, which is igneous rock containing important minerals such as silica and alumina from Akara Resources Public Company Limited. The binder material is mixed with a microbial solution, resulting in bio-cement with a calcium-alumina-silica compound structure that is resistant to salt erosion and can repair itself when micro-cracks occur. The microbes will create white calcium carbonate crystals to close the cracks. It can replace traditional cement sheets or HDPE plastic sheets that are commonly used to retain water in the soil, which tend to deteriorate and cause microplastics to accumulate in the soil.

In this bio-cement test, we will install 75 x 75 cm. and 8.5 cm. thick bio-cement sheets into lysimeter tanks where rice is grown and where rice is not grown to study the rate of evapotranspiration in plants and the rate of water evaporation in soil, respectively, as well as the efficiency of bio-cement in delaying water seepage and preventing salinity from the ground. The test will be conducted once per rice-growing cycle or approximately 4 months before the bio-cement is brought up to examine its self-repair efficiency and salinity resistance at every stage of cultivation,” Asst. Prof. Dr. THIDARAT BUNSRI said.

Civil Engineer, Research and Development Office, Royal Irrigation Department, added, “If the experiment is successful, in addition to solving the problem of saline soil and soil that does not hold water, bio-cement can also be applied to solve other problems, such as studying the use of bio-cement in irrigation canals. With its self-repairing properties when small cracks occur, it will reduce water loss from leakage and increase irrigation efficiency.”

The assistant manager of science and health at Akara Resources Public Company Limited said about this collaboration that “The company works in mining and has waste from production as mineral waste, which can strengthen the bio-cement. Therefore, we fully support and are very pleased that we are part of solving the problem of this area.”

A representative from CPF (Thailand) Public Company Limited brought eggshells for the research team to use as an important ingredient in bio-cement, saying, “Normally, eggshells from our hatcheries are used by farmers in the area to nourish the soil. However, this is the first time that eggshells have been developed into food for microorganisms that will help repair the bio-cement to be stronger and maintain its quality for a longer period of time. This is another source of pride for the company to participate in creating innovations to solve problems in the area, and we are happy to support eggshells in other areas that the research team would like to develop further, as we have hatcheries covering the entire country.”

Asst.Prof.Dr. THIDARAT BUNSRI said, “If this project is successful, the resulting bio-cement will be formulated to be used with a 3D printer to produce artificial coral reefs or developed into bio-concrete that may be used in construction to increase underground water storage. In addition, the bio-cement may be coated with manganese and zinc to improve the quality of wastewater from households, which will recycle wastewater for use in agriculture when there is a water shortage.”

This project is not only an important step in the development of agricultural technology, but also helps create sustainability and is environmentally friendly. The project is currently in the research and testing phase, which is expected to be expanded and applied to other areas in the near future.