One of the essentials for EV car owners is an EV charger, which will charge the battery in an EV car. In the future, if the number of EV cars increases, the need to install EV chargers in residences and buildings will increase, either for use with new EV cars or to replace old and damaged EV chargers. However, the EV chargers that car manufacturers install for car buyers, including those sold in stores and online, are all imported from abroad. Most buyers find it difficult to know how standard and safe the EV charger is because Thailand has not yet issued a standard for EV chargers for homes.

One small step towards this approach is the EV Charger Cabinet, the work of three undergraduate students from the Faculty of Engineering, King Mongkut’s University of Technology Thonburi (KMUTT).

One of the students who created the work said that he and his friends had the opportunity to watch a clip about making an EV Charger for EV cars by a Thai technician, which the advisor sent to them when they were studying in their third year, second semester. So they consulted the teacher about whether the knowledge of electrical engineering that they had studied for three years and in their fourth year could be used to create a circuit board box to control the power supply to EV cars. This led to the fourth year project. At that time, our expectation was to create a circuit board that could control AC charging to the same standard as the EV Charger boxes available on the market.

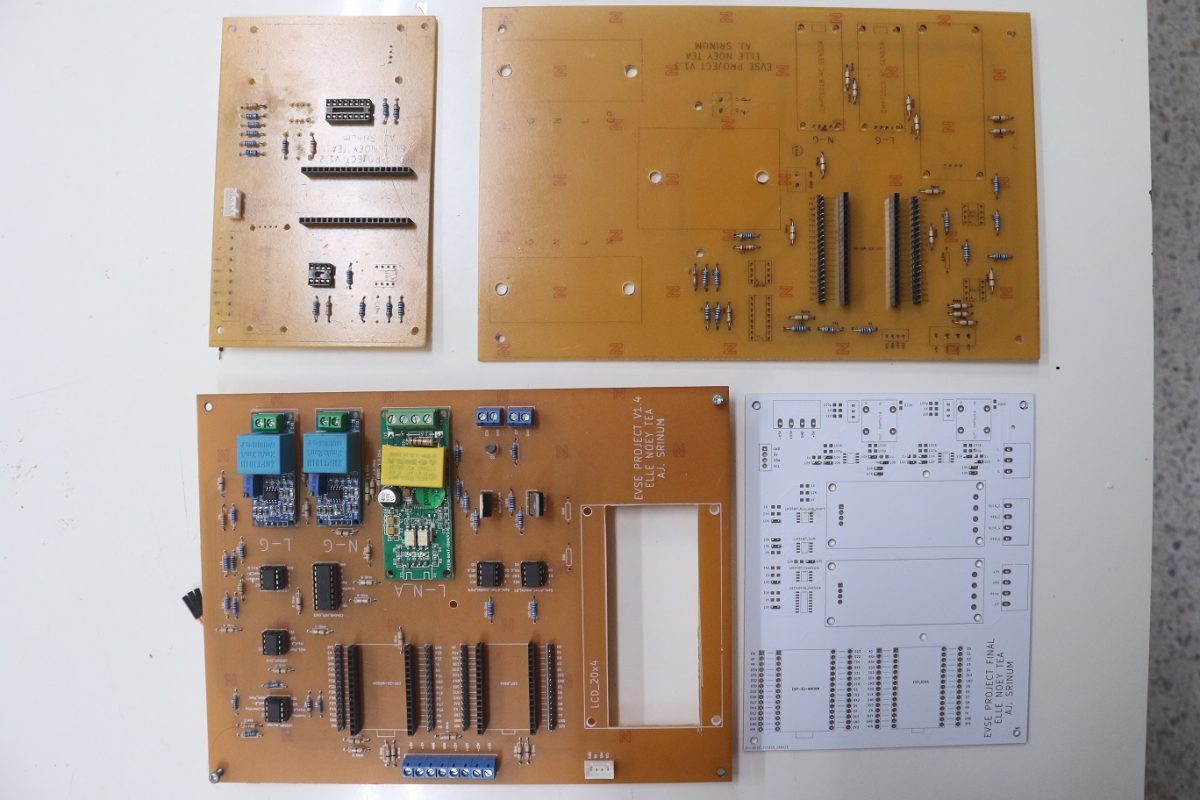

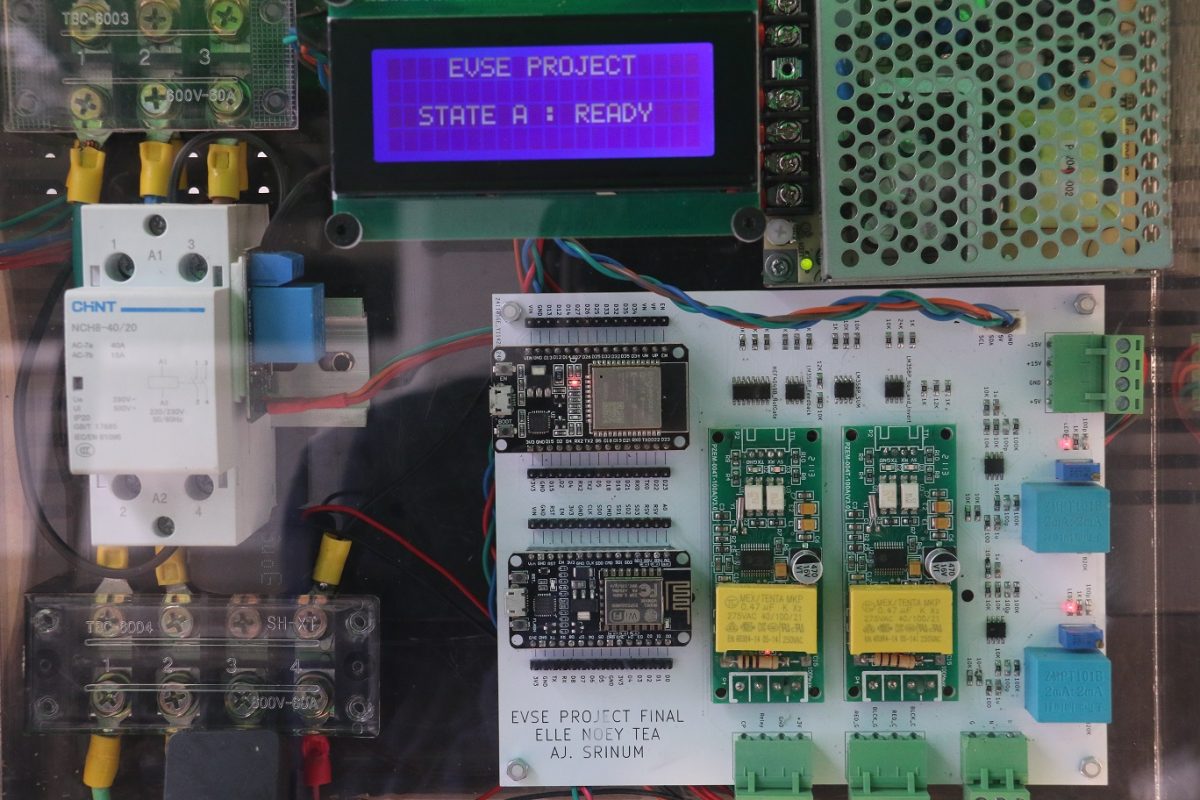

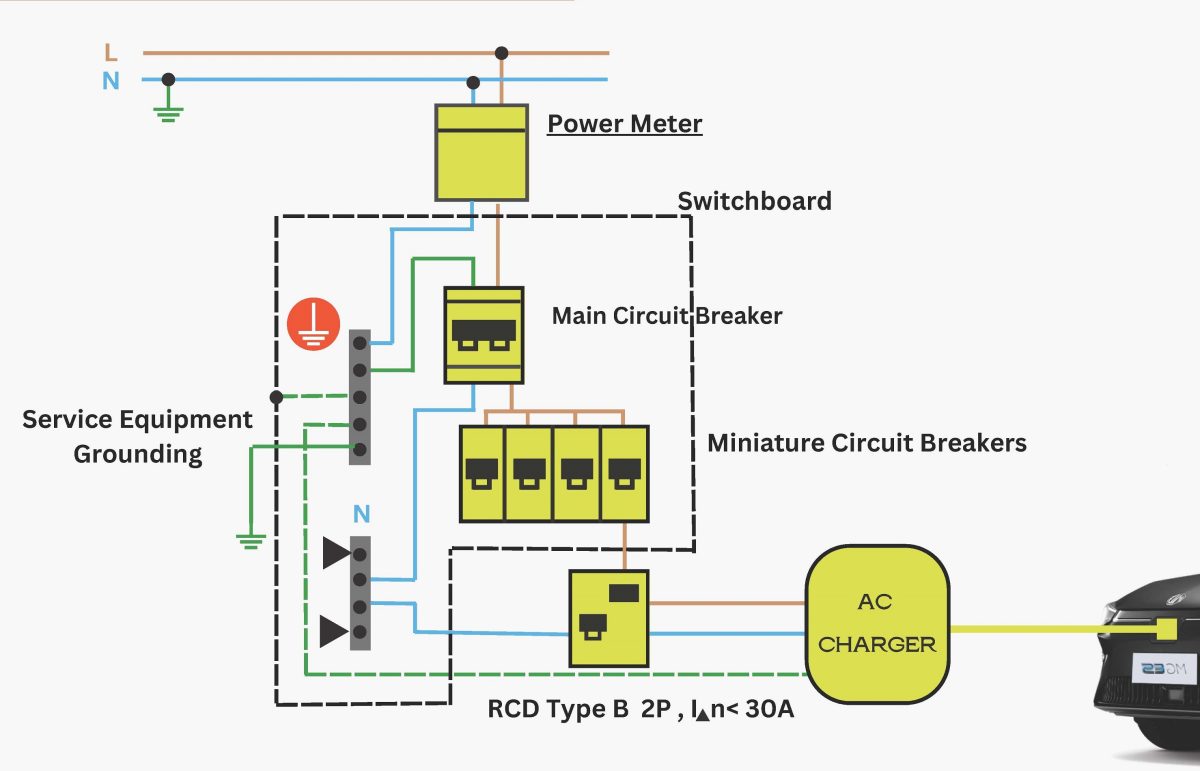

“In the EV Charger box available on the market, there must be a circuit to prevent electrical leakage, a grounding system, a voltage control system, a signal communication system to check the charging situation, and a power cut-off system when a problem occurs. Each system has a clear international standard. Therefore, in designing and creating a circuit board to control these systems, the goal is to adjust the signal values that occur during the charging experiment to meet the international standard (J1772). In the 4th year, the first semester will be a simulation study through the program before creating the circuit board and testing it for real in the second semester. In my part, I am mainly responsible for the hardware, such as making the printed circuit board (PCB).

The coder and software writer talked about the operation of the EV Charger that was developed. When the charger plug is plugged into the car, the system will immediately communicate with the car when it is plugged in. When the check is complete, it will automatically start charging itself and stop charging when the battery is charged to the specified value or at the specified time (can be selected). At every step, there will be a message to inform the car owner via the cabinet screen and via Wifi to be displayed on the mobile phone screen. This prototype EV Charger box can be used with both 1-phase AC power with a maximum charging power of 16 amps or 3-phase AC power with a maximum charging power of 32 amps. All processes are in accordance with all international standards.

Another team member who is mainly responsible for finding information about the standards of various systems on the EV Charger circuit board said, “Another duty of mine is to procure, in addition to the electronic components, including ordering printed circuit boards (PCB) designed by Sittidech (T), as well as contacting a breaker manufacturing company to request a circuit breaker for leakage and overcurrent protection to be used in this project free of charge, and coordinating to request an old cabinet frame from the university to be made into a charger cabinet, making the EV Charger, which reduced the actual equipment cost from tens of thousands of baht to less than ten thousand baht. In addition, we have gained knowledge that now we can make the second and third EV Charger boxes to be of the same standard as boxes priced in the tens of thousands on the market, with an equipment cost of no more than 5,000 baht.”

Asst.Prof.Dr. SUPAPONG NUTWONG, a lecturer at the Department of Electrical Engineering, Faculty of Engineering, and an advisor, added that the project to develop a charging control circuit board for EV cars can be further developed into the work of the next generation in many aspects, such as developing it to be able to use with DC charging, enabling a set of circuit boards to charge more than one car at the same time, and a data system and direct control of mobile phone charging. All of this will be beneficial to Thai entrepreneurs who are interested in producing EV Chargers for sale, both in terms of selecting standard materials and equipment at expensive prices and in terms of setting up various EV Charger signals to meet international standards, and possibly including Thai EV charger standards that may be announced in the future.