With a sweet taste The perfect crispness makes “Phulae Pineapple” a GI product of Chiang Rai Province that has orders from China both in the form of fresh fruit. Fruits are peeled or trimmed before being exported every year consecutively. Until now, there is more than 50,000 rai of this type of pineapple planted in Chiang Rai Province, with a production of more than one hundred thousand tons per year. However, the production of Phulae pineapple has a lot of leftover material, which has the potential to be transformed into a high-value product. The process of producing pineapple in various steps Carbon emissions due to foreign import regulations must be taken into account. Including consumers who give importance to Therefore, research is being done to create additional value from the remaining materials in the production process and to obtain figures on the greenhouse gas emissions of Phulae pineapple products by means of collecting data and using photographs. By air It is important to make the Phulae pineapple of Chiang Rai Province Maintain competitiveness in the Chinese market as well as in other countries. continuously

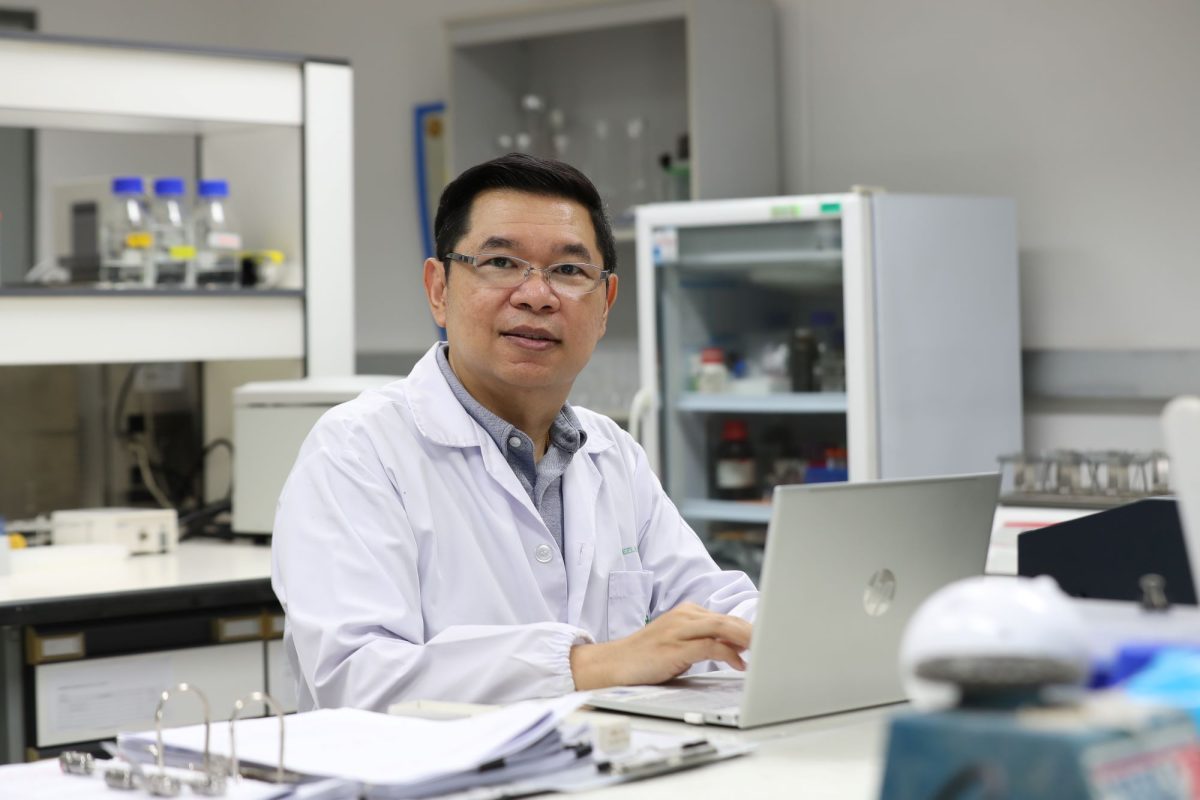

This is the origin of the project of using innovation to increase the value of waste materials and evaluating the carbon footprint in the production and processing chain of Phulae pineapple in Chiang Rai Province. With the support of the National Research Council of Thailand by Assoc. Prof. Dr. Anak Khanthachawana, Lecturer in the Faculty of Engineering. King Mongkut’s University of Technology Thonburi (KMUTT), as the project leader, said that under this 1-year project (starting operations in April 2023) it consists of 2 sub-research areas: (1) carbon footprint data analysis The process of planting and processing Phulae pineapple throughout the production chain includes designing mathematical processes and algorithms together with using images from unmanned aerial vehicles for analyzing carbon footprint throughout the process of growing Phulae pineapple. and (2) guidelines for adding value and/or creating innovation from the use of leftover materials in the Phulae pineapple processing process according to the Zero waste approach, with the main goal being to raise awareness among farmers or entrepreneurs about the impacts. to the environment that affects the industry as a whole This will lead to a change in the production and management model that is beneficial to both the environment and the Phulae pineapple market both in Thailand and abroad.

“If we have numbers on greenhouse gas emissions from farms to factories, It will be the starting point to obtain carbon labels that are accurate and can actually be attached to products. This information is also important information for communicating with farmers and entrepreneurs. To lead to cooperation in changing methods both on the farm and in the factory. To reduce the number of carbon emissions on the carbon label of Phulae pineapple products has been reduced. This will lead to greater acceptance of the product by importers and consumers abroad. At the same time, information from Mae Fah Luang University that has done research with us both in this project and before. It was found that pruning Phulae pineapples for export There will be various leftovers, including leaves, bark, and other parts, up to 60 percent. Turning leftovers into new and valuable products will not only create income and help reduce waste. It also reduces greenhouse gas emissions resulting from natural decomposition. which can be used to reduce the numbers on the carbon label in another way.”

Drones and artificial intelligence Analysis of greenhouse gas emissions

Analysis of carbon footprint data of the Phulae pineapple growing process Assoc.Prof.Dr. SONGKEART PHATTARAPATTAMAWONG From the Faculty of Engineering, KMUTT, a member of the research team, said that data must be collected on the amount of all resources used from the planting process to the harvesting process, such as the amount of water, type and amount of fertilizer, chemicals, fuel. To use all the data to calculate the amount of carbon that is generated and released into the atmosphere from the use of all resources.

“Use data on resource quantities such as chemical types, quantity and frequency of use. To be converted into the amount of greenhouse gas emissions or carbon emissions. Using the calculation method of the Greenhouse Gas Management Organization. (Public Organization), which is a guideline for certification within the country.”

The results found that “leftover materials”, corks and leaves after harvesting produce the “most greenhouse gases”. If left on the farm until natural decomposition occurs, carbon dioxide will be released. Accounted for 58 percent of all farm processes, followed by fertilizer use (26 percent) and fuel use (15 percent), respectively.

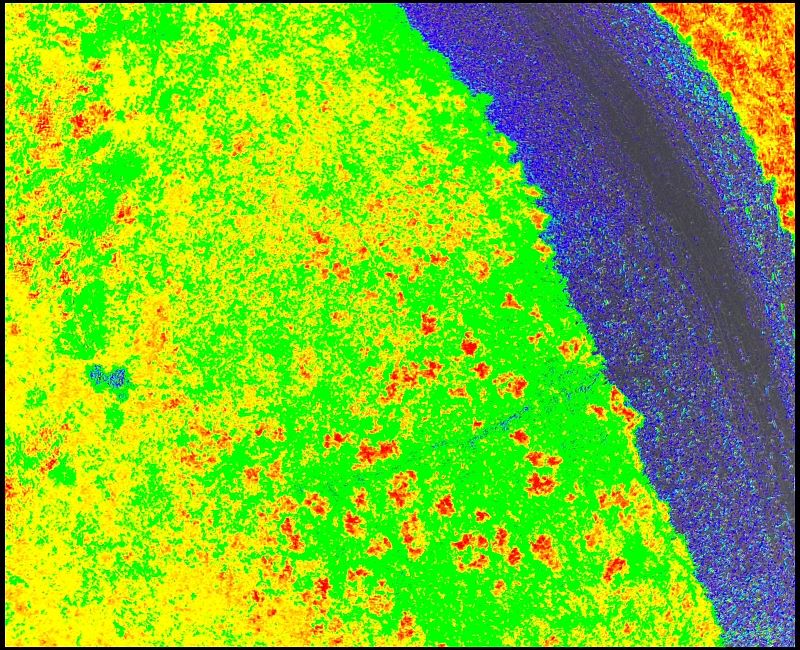

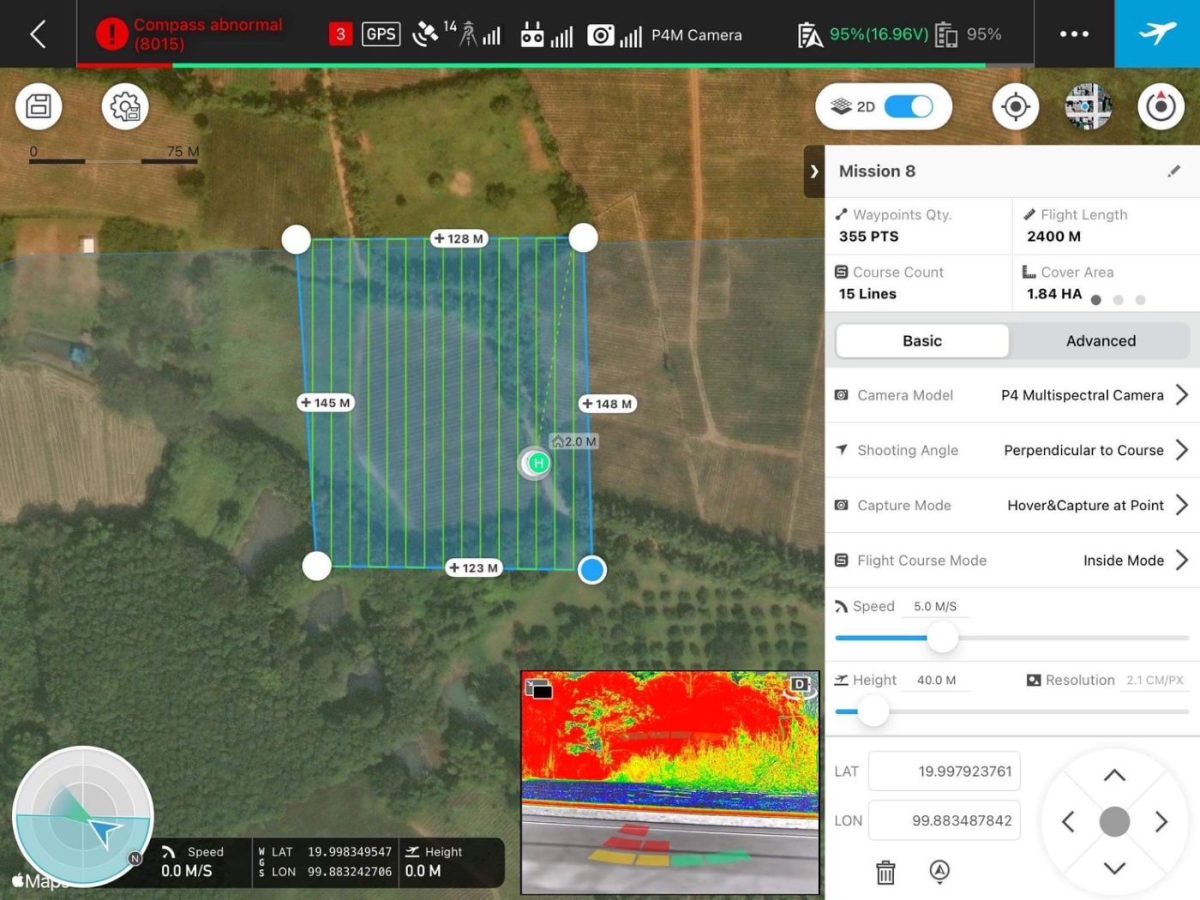

Asst. Prof. Dr. Sonkitja Bunprong from the Faculty of Social Sciences Kasetsart University Researchers joining the project use “drone” technology to capture aerial images together with machine learning algorithms and artificial intelligence. Analyze the database from the amount of greenhouse gases obtained from collecting data on resource use to process/estimate the amount of carbon that will occur in each period from planting to harvesting. It is said that drones can quickly collect photos of pineapple growing areas. Fast and accurate and can be used to continuously track changes in planting areas. The images captured by the camera capture images in different wavelengths. including red, green, blue and infrared ranges

“By creating an algorithm or equation that calculates the amount of carbon released into the atmosphere that occurs in pineapple farms. By combining wavelength data from drone flights with a database of carbon quantities obtained from using farm resources, the AI system calculates and creates an algorithm that shows the relationship between these two sets of data.

The first phase of the project uses data from flying drones over 7 rai, 7 times per rai, or equal to 49 data sets. The creation of an AI carbon calculation algorithm makes it possible to create the desired prediction model in a short time. and precise And most importantly, when adding new data, the AI can improve the calculation equations to be more accurate.”

For the second phase of work that will begin in the middle of this year, Asst. Prof. Dr. Sonkitja said that photos from THEOS 1 and 2 satellites of Thai people will be used instead of photos from drones. To expand the results to a wider area of pineapple growing areas. In addition, Assoc. Prof. Dr. Songkiat said that there will be an analysis of greenhouse gas emissions in the production process of factory-cut pineapples that will provide information on the carbon cycle throughout the loop. Production chain leading to certification “Carbon label” of Phulae pineapple products next

Increase the value of leftovers from Phulae pineapple.

In the research section “Innovation to increase the value of waste materials from Phulae pineapple processing” developed by a research team from the Faculty of Biological Resources and Technology King Mongkut’s University of Technology Thonburi in collaboration with Mae Fah Luang University Chiang Rai Province In taking the waste peel of the Phulae pineapple and processing it into a high-value substance product such as rare sugar. which is a high value sweetener Used in the food industry Including dietary supplements that are beneficial to the health of consumers.

ASSOC.PROF.DR. VARIT SRILAONG, Dean of School of Bioresources and Technology, KMUTT, head of the research project, said, “From analyzing the quality of leftover Phulae pineapple buds, the research team found that there are many important substances that have sufficient potential. and can be extracted into rare sugars which is a high value substance “Rare sugars” are single sugar molecules that are hard to find in nature. Found in small quantities Even though the structure is similar to normal sugar. But it has a more special feature: sugar gives less sweetness. But it has the ability to promote probiotic microorganisms. which are good microorganisms in the body that grow well Including inhibiting the growth of harmful microorganisms in the body. Resulting in better health It meets the needs of people today.”

The extraction of high-value sugars from pineapple peels began with Mae Fah Luang University, where cut-off pineapple buds were dried before being sent for chemical properties analysis. and extracted into rare sugars at the Faculty of Biological Resources and Technology The dried pineapple buds are ground into a fine powder to analyze their properties and are used for extracting rare sugars. By choosing to use biological methods instead of using chemicals in traditional extraction methods. By using microorganisms that have the ability to efficiently extract rare sugars from pineapples. The microorganisms and pineapple interact in a bioreactor. that controls many variables such as temperature, pH, and time until it becomes a sugar extract containing rare sugar ingredients Before being made into powdered sugar through the spray drying process, the value of the resulting product is many times higher when compared to the price of sugar commonly consumed. In addition, it can be developed into products for the health of consumers and are environmentally friendly products at the same time.”

Assoc. Prof. Dr. VARIT added that Data from past studies by various groups of researchers It was also found that in addition to the rare sugars that are extracted, they are beneficial to the good microorganisms in the body. It also has anti-cancer properties. Antioxidants Prevent diabetes, obesity and fat clots in the arteries. There is also the possibility of using it in dietary supplements. and used to maintain the quality of agricultural products This is a problem that the research team intends to do in the future as well.